This machine is suitable for printing such packing materials as paper, PE, PP bag, cellophane and roll material, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Printing sample effects:

Printing width Item | 600mm | 800mm | 1000mm | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm |

Printing color | 4(PC:4+0,3+1,2+2) | |||||||

Printing length | 7.5"-40"/7.5"-50 (190~1250mm) | |||||||

Thickness of plate | 1.14mm.1.7mm 2.28mm.2.84mm. 3.94mm Customized is available | |||||||

Heating method | Electricity heating with Big oven | |||||||

Max.oven temp | Max. 80ºC(room temp. 20ºC) | |||||||

Web fixing method for un/rewinder | Safety chuck+ Air expanding shaft | |||||||

Printing plate lifting system | Hydraulic press control | |||||||

Menchanical speed | 100m/min | |||||||

Printing speed | 60m-90/min according to different material | |||||||

Anilox cylinder | Ceramic anilox roller | |||||||

Register precision | Longitude:±0.25mm,Transverse±0.25mm | |||||||

Rewinder/UnwinderDIA | φ600mm~φ1000mm | |||||||

Master motor | 3.7kw | 3.7kw | 5.5kw | 5.5kw | 7.5kw | 7.5kw | 11kw | 11kw |

Unwinder motor | 1.1kw | 1.5kw | 2.2kw | 3.0kw | ||||

Rewinder motor | 1.5kw | 2.2kw | 3.0kw | 3.7kw | ||||

Electrical heater | 14kw | 16kw | 20kw | 22kw | 24kw | 26kw | 28kw | 30kkw |

Blower of heater | 1.5kw*2 | 1.1kw*3 | 1.1kw*3 | 1.1kw*3 | 1.5kw*3 | 1.5kw*3 | 2.2kw*3 | 2.2kw*3 |

Blower of nature wind | 0.75kw | 0.75kw | 1.1kw | 1.1kw | 1.1kw | 1.5kw | 1.5kw | 1.5kw |

Inking motor | 370w | 750w | 750w | 750w | 750w | 750w | 750w | 750w |

Master frequency converter | (Panasonic)/ (Toshiba)transducer Japan | |||||||

Bearing | Japan(NSK) | |||||||

Unilateral bearing | ASNU(Germany) | |||||||

Weight | 4500kg | 4750kg | 5000kg | 5250kg | 5500kg | 5750kg | 6000kg | 6300kg |

Master Power | 25k | 27kw | 34kw | 37kw | 43kw | 47kw | 55kw | 58kw |

Dimension(L*W*H) | 4.8m* 1.8m* 2.8m | 4.8m* 2.0m* 2.8m | 4.8m* 2.2m* 2.8m | 4.8m* 2.4m* 2.8m | 4.8m* 2.6m* 2.8m | 4.8m* 2.8m* 2.8m | 4.8m* 3.0m* 2.8m | 4.8m* 3.2m* 2.8m |

1.Easy operation, flexible starting, accurate color register.

2.The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3.Manual printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4.The printing ink is spread by the anilox cylinder with even ink color.

5.Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6.360°continuous and adjustable longitudinal register device.

7.The frequency control of motor speed adapts to different printing speeds.There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Suitable material:

| Paper series: Kraft paper:40-350gsm, single-sided coated paper:30-350gsm, copy paper:15-350gsm, firecrackers and paper:40-350gsm, paper money and incense:25-350gsm, silicone paper:50-350gsm, coated paper:30-350gsm, dust-free paper:25-350gsm, release paper:40-350gsm, composite paper:30-350gsm, thermal sensitive paper:30-350gsm... |

| Plastic film series: PVC:10-120micron, OPP:10-120micron, PE:20-120micron, PET:20-120micron, CPP:20-120micron... |

| Woven:15-120micron, Weave fabric:15-120micron, Toilet paper, leather... |

| Specific details welcome consultation |

Main configurations:

Optional device(need extra money to get perfect machine)

1.PLC Control

2.Auto pneumatic/hydraulic loading&unloading.

It is easy to mounting the material.

3.Joist barrow

It's easy to lift the materials

4.Video Inspection

check the printing quality on the video screen.

Transport:

The machine is split according to the size of the container, and packed by film to prevent dust accumulation, fixed by nails, or packaged in wooden boxes specified by the customer (the price is different according to the size of the model)

After sale serveice:

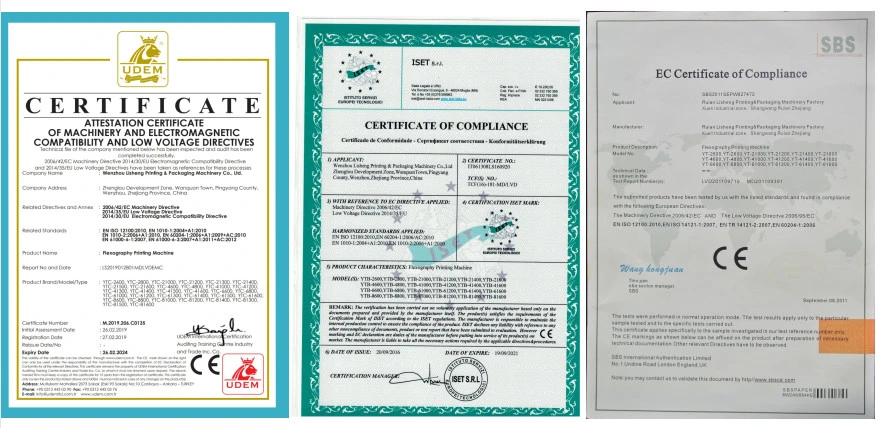

Certifications:

Our Company:

FAQ

1.Are You a Factory or Trading Company?

We are a factory, with 20 years experience on machines, our products sell very well all over the world.

2.Where is your factory located? How can I visit there?

Our factory is located in Ruian Zhejing China. The nearest airport is Wenzhou airport. It's about 40 minutes by plane from Shanghai (5 hours by train). All our cliens, from home or abroad, are warmly welcomed to visit us.

3.What can the machine print on?

Our machine is multifunction, can do roll to roll printing, such as paper, plastic, woven,nonwoven and so on .

Surely, you can send us your products, and we'll offer you the proper machine.

4.Can I get some samples? How can I get it ?

Yes, we can send you some free sample, but you are reponsable for delivery charages of TNT or DHL.

5.How about the after service?

We can arrange engineers to service overseas.

6.Why choose Lisheng Machinery?

We are one of leaders in this field(in China). Our high-quality products and service enabled us to expand our market from china to more than 60 countries.